Description:

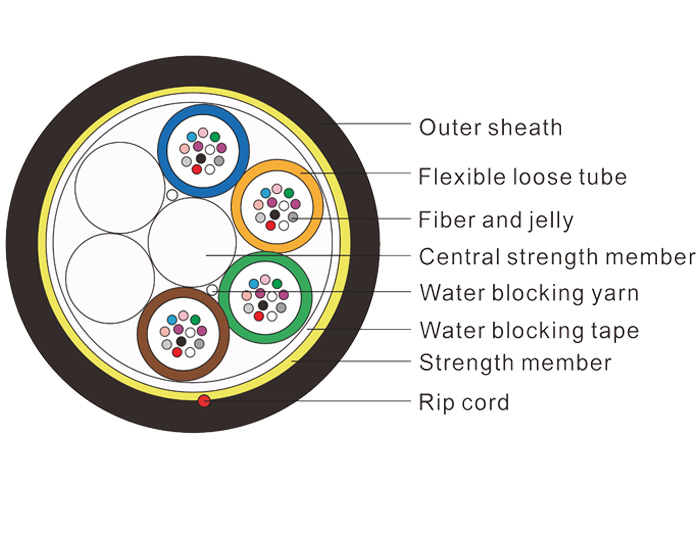

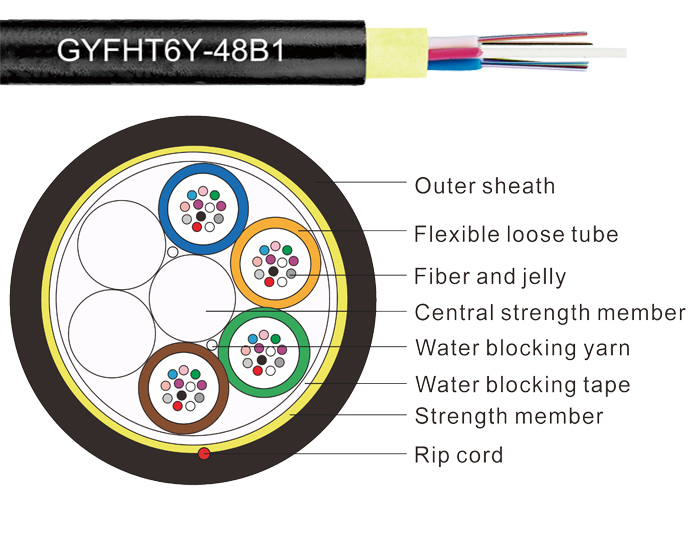

GYFHT6Y, Non-Armored Flexible Loose Tube Duct Optical Fiber Cable. The fibers, 250um, are positioned in a loose tube made of a high modulus plastic. GYFHT6Y adopts a new Flexible loose tube, made of a new material, which is softer than normal PBT loose tube and more easily to install and splice in the outdoor field. The tubes are filled with a water-resistant filling compound. A FRP locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The water-blocking tape moisture battier is applied around the cable core, After water-blocking tape has a layer of aramid yarn as the strength member over the water-blocking tape. Finally, the cable is completed with a PE outer sheath.

Feature:

S-Z stranded (up to 144 fibers), Gel-filled.

Low loss, low dispersion.

Flexible Loose Tube could be stored in the joint box instead of only fibers to reduce fiber splice and installation time, easy to future maintenance.

The loose tube excellent bending performance with a minimum bending radius ≤ 3*tube OD.

Good mechanical and temperature performance.

High tensile strength of stranded wires meet the requirement of self-supporting and reduce the installation cost.

A specially designed compact structure is good at preventing loose tubes from shrinking.

Crush resistance and flexibility.

Non-Metallic Central Strength Member.

Longitudinal wrapped water-blocking tape moisture barrier.

Loose tube filling compound.

Reasonable design, precise residual length control and cabling process make the cable have excellent mechanical and environmental performance.

In accordance with IEC, ITU, and EIA standards.

Application:

Duct, Indoor and Self-supporting Installation.