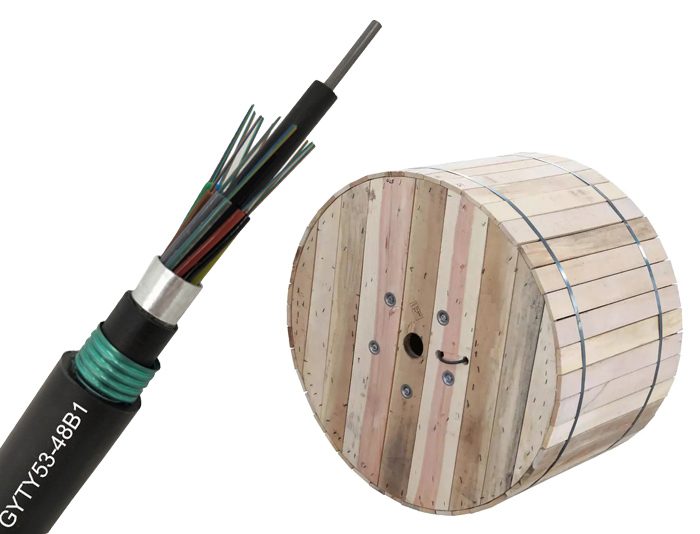

Description:

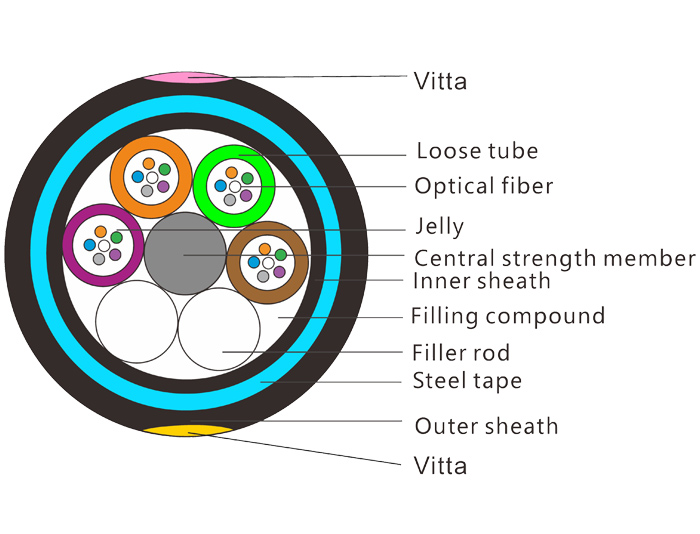

GYTY53, Steel Tape Armored Stranded Loose Tube Optical Fiber Cable With Dual-Jacket With Color Stripe is Direct Buried Fiber Optic Cables. The fibers, 250um, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire as the central strength member. For some fiber cables duct underground, a layer of polyethylene (PE) needs to be added around steel wire, locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. A Corrugated Steel Tape (PSP) is applied around the core, which is filled with the filling compound to protect it from water ingress. Then, the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath. Finally, the fiber duct cable is completed with a PE outer sheath.

Feature:

S-Z stranded, Gel-filled.

Fiber Optic Cable Core up to 288 fibers.

G652D, Low loss, low dispersion.

Good mechanical and temperature performance.

High-strength loose tube that is hydrolysis resistant.

Special tube filling compound ensures a critical protection for the fiber.

A specially designed compact structure is good at preventing loose tubes from shrinking.

Crush resistance and flexibility.

Inner PE Sheath & Outer PE Sheath.

With Red & Yellow color stripes on outer sheath or Customized.

Metallic Central Strength Member.

Longitudinal wrapped Corrugated steel tape moisture barrier.

Loose tube filling compound.

100% cable core filling compound.

Reasonable design, precise residual length control and cabling process make the cable have excellent mechanical and environmental performance.

In accordance with IEC, ITU, and EIA fiber cable standards.

Application:

Outdoor Direct Buried.